Vibro-Shock Testing: Principle, Application, and Features

In the production process of products, in order to ensure the structural strength of the products, random tests or shock test are often performed on the products. Did you know the vibro-shock? Vibro-shock is a kind of test in which the excitation signal to the product is shock pulse with random properties. The APSD target spectrum is defined in the same way as the random test, and the interval of the shock pulse needs to be defined at the same time.

PART 1 - Application

In engineering fields such as defense, vehicles, and transportation, a large amount of environmental vibration is vibro-shock. For example, the vibration of gun shooting is a typical vibro-shock signal.

Vibro-shock is commonly used in vibration tests for road simulation.

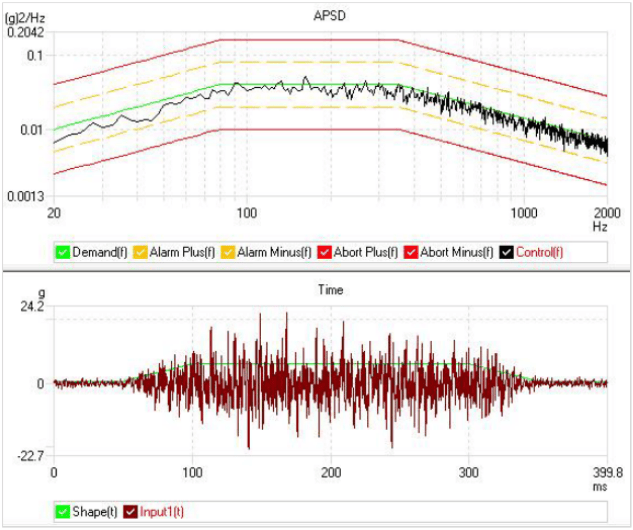

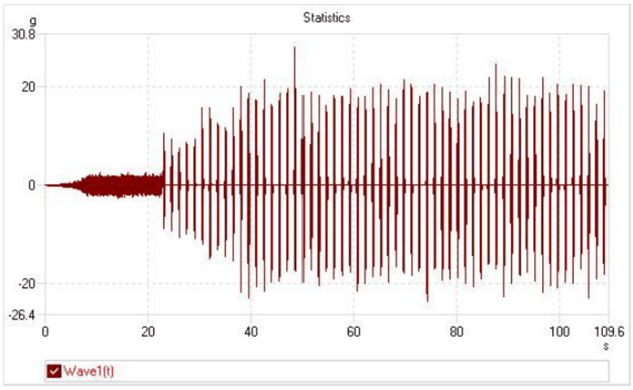

The following is the operating curve of the vibro-shock module

PART 2 - Control Principle

Vibro-shock control process for VENZO 880 controller:

The input of the vibration controller receives the vibration signal of the sensor. According to the random spectrum, dispersion spectrum or shape set by the user, the reference spectrum is modified in real time, and the drive spectrum is obtained by compensation, and generates the target spectrum signal that meets the requirements, and outputs it to the shaking table to realize random impact. vibration control.

PART 3 - Features

In the Vibro-shock module of the VENZO 880 vibration controller, the broadband random spectrum can be set in the form of table customization or imported data, and the target effective value can be adjusted in the form of "g", "dB" or "%". One-click 'zoom' automatically adjusts the timing of the shape spectrum to match frame times of different sizes. Before the test, we can preset the number of pulses, pulse interval and whether to count the number of test pulses for each level test in the plan table, or adjust the test level and test process during the test.

In order to better meet the user's test requirements, the vibro-shock test of the VENZO 880 controller is also equipped with some special test functions.

Dispersion Vibration Test

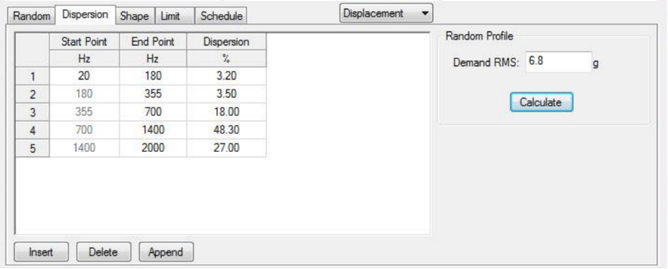

For Example, the dispersion spectrum is shown in the table:

| Frequency | 20-180Hz | 180-355Hz | 355-700Hz | 700-1400Hz | 1400-2000Hz |

| Dispersion | 3.2% | 3.5% | 18% | 48.3% | 27% |

| RMS | 6.8g | ||||

The settings are as follows:

Enter demand RMS and click "Calculate" to automatically match the target spectrum.

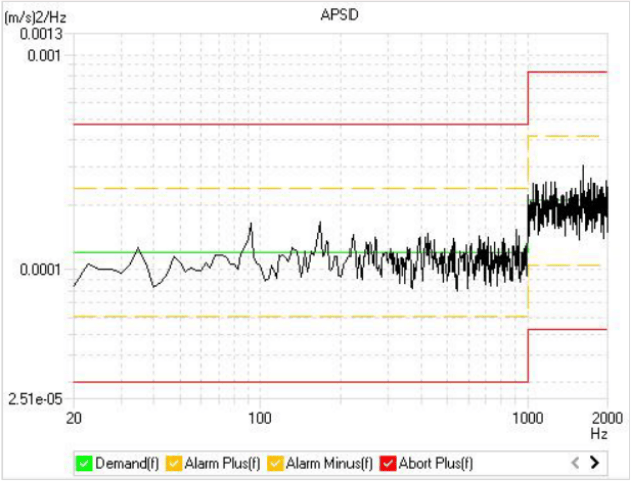

Non-acceleration control

In the Vibro-shock module of VENZO 880 controller, except acceleration control, Users can also select other physical quantities other than acceleration control, such as normal force, velocity, displacement, etc., from the drop-down list of control physical quantities.

Shaker parameter limits will not work in this mode, so the user needs to carefully define the target spectrum to ensure the safe operation of the test.

The following figure shows the running curve in the speed control mode.

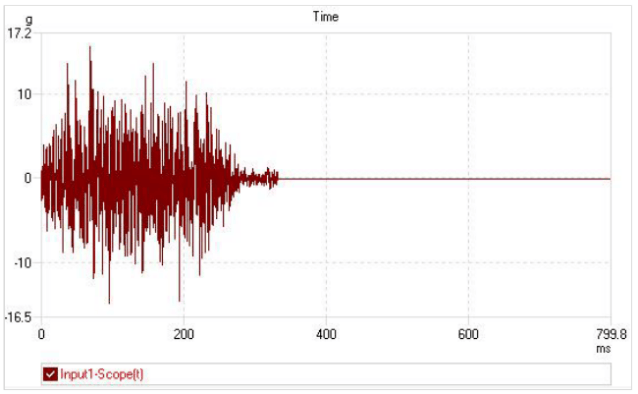

Oscillography signal and historical signal recording

In the Vibro-shock module of the VENZO 880 controller, the oscilloscope window can display the segment time domain signal in real time, and the segment size can be adjusted according to actual needs.

At the same time, in the Vibro-shock module of the VENZO 880 controller, the time domain signal can also be recorded in real time.

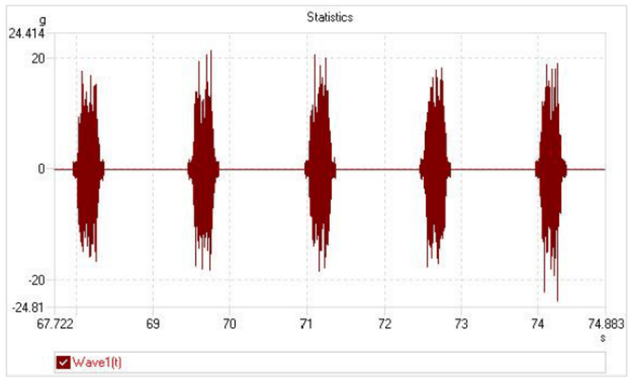

The following figure shows the recording of the time domain signal.

Zooming in on the local signal clearly shows that the random signal is distributed in the form of spaced pulses.